उच्च गुणस्तरको PVC पाइप उत्पादन लाइन

सोधपुछ पठाउनुहोस्

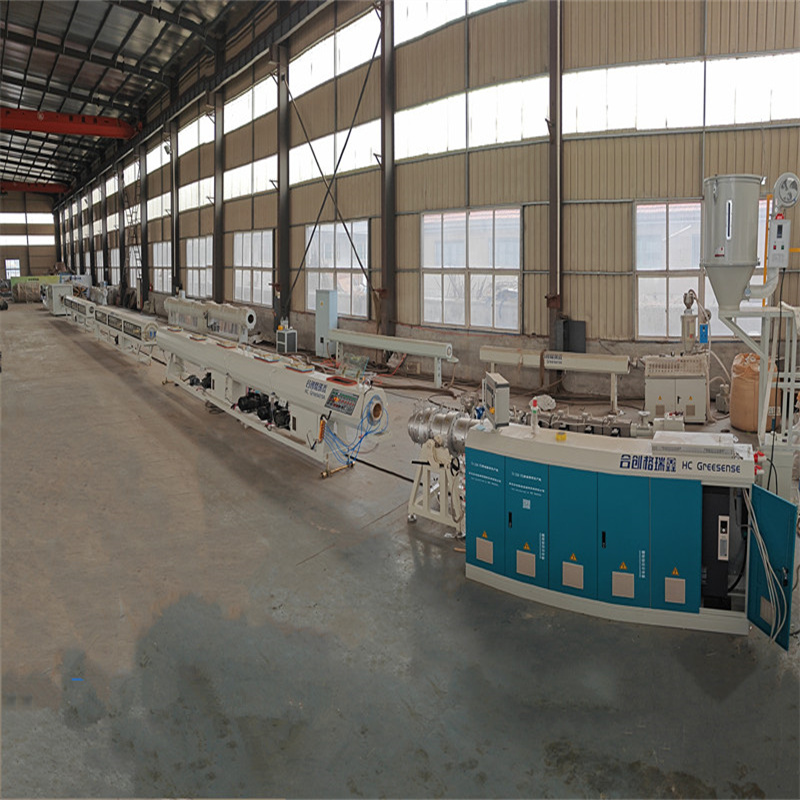

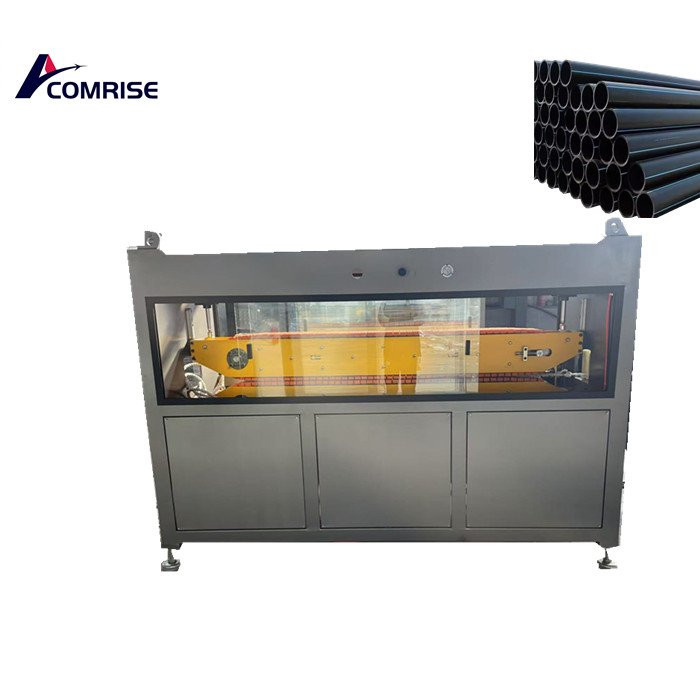

High quality PVC pipe production line

1. Ensure long-term stable operation and long service life

2. Compact structure, low noise, high load-bearing capacity, high transmission efficiency, ensuring long-term stable operation

3. Heating is controlled by solid-state relays (S.S.R) to achieve stable heating; (SSR) No sparks or noise, improving safety production.

4. The Siemens PLC control system has reliable technology, automatic and intelligent functions, which are used for centralized control and monitoring of extrusion production lines, acilitating easy operation.

(1)SJSZ conical twin-screw extruder

1.1 Siemens PLC

1.2 Quality screws and barrels

1.3 Air cooled ceramic heater

1.4 High quality gearbox and distribution box

1.5 Better gearbox cooling 1.6 Advanced vacuum system

1.7 Simple Cable Connection

(2)PVC pipe mold head moldModule

2.1 Mobile Device

2.2 Mold head rotation device

2.3 Numerical Control Machining

2.4 High quality materials

The extrusion die head adopts a bracket structure, and each material flow channel is evenly placed. Each channel undergoes heat treatment,

Mirror polishing and chrome plating ensure smooth material flow.

The mold head adopts modular design, which is easy to change the pipeline size, assemble, disassemble and maintain. We can also produce single-layer or multi-layer pipelines.

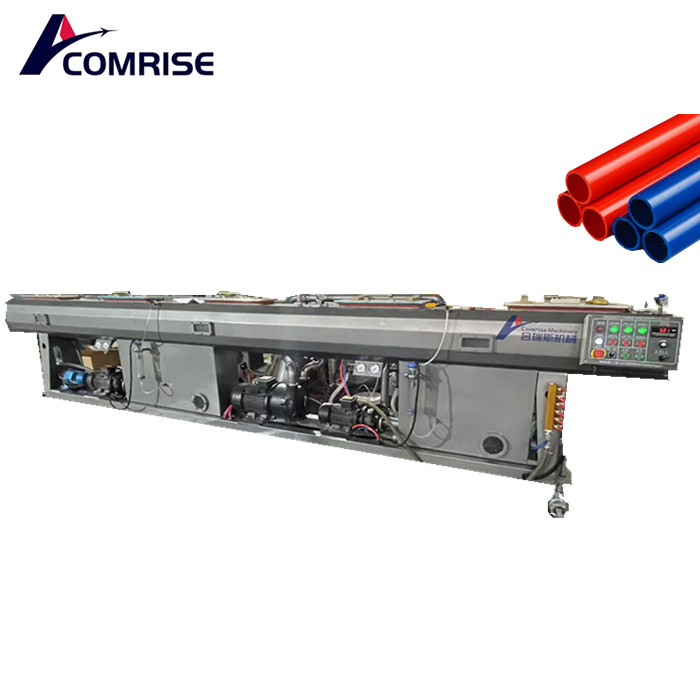

(3)Vacuum shaping tank

3.1 Strong cooling of calibrator

3.2 Better pipeline support

3.3 Muffler

3.4 Pressure relief valve

3.5 Dual circuit pipeline

3.6 Water and Gas Separators

3.7 Fully automatic water control

3.8 Centralized drainage system

Vacuum tanks are used for forming and cooling pipelines to achieve standard pipeline sizes. We use a dual chamber structure. The first room is

Ensure very strong cooling and vacuum functions within a short length. When the calibrator is placed in front of the first chamber and pipeline

The shape is mainly formed by the calibrator, which ensures fast, better shaping and cooling of the pipeline.

(4)Traction machine

The towing unit provides sufficient traction to stably pull the pipeline. According to different pipeline sizes and thicknesses, our company will customize the traction speed, number of claws, and effective traction length. In order to ensure that the extrusion speed of the pipeline matches the forming speed and to avoid deformation of the pipeline during traction.

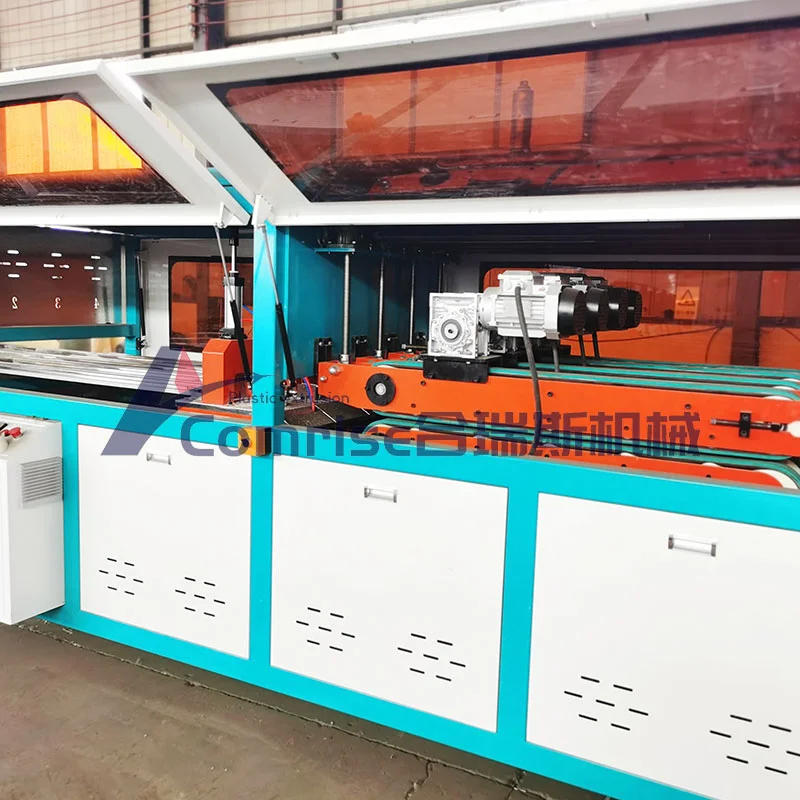

(5)Cutting machine

5.1 Aluminum clamping device

5.2 Advanced Hydraulic System

5.3 Dust collection system

The cutting blade is controlled by Siemens PLC and has chamfering function, working together with the towing unit for precise cutting. customer

They can set the length of the pipeline they want to cut.

Welcome to inquire

GET A QUOTATION NOW